|

| Intello-Plus on the interior of our walls. |

This is the first of what I think will be at least a couple of posts on our Air-Sealing strategy for the house. Air-Sealing is one of the most important parts of the our energy-efficiency strategy: without proper air-sealing, all our fancy super-insulation and passive-solar heating wouldn't make a lick of difference. We'd just take all that nice conditioned air and throw it away, as cold air seeped in through the cracks.

This house is totally sealed on the interior and uses a Zender HRV (a Heat Recovery Ventilator) to move air into and out of the house. We used a similar

Zehnder unit last summer on the Solar Decathlon project and were very happy with how easy it was to install and set up. So we'll give it a shot again. But HVAC is a post for another time. Right now its all about Air-Sealing!

To let people survive inside a house you need a certain amount of 'fresh' air (for . . . you know: breathing). Also, you want to take all the smelly bathroom, kitchen and 'stale' air and send it outside - (but again - heat recovery and ventilation is another post)

In a 'normal' house, this fresh air just comes in through cracks in the walls, around the windows, under the doors and lots of other places. But the new cabin uses a machine (the HRV) to, in a controlled way, bring this fresh air into the house and take the stale air away. The thing is, this machine can only work well if the rest of the house doesn't let the air move through cracks, windows, doors and . . . well: you get it.

In addition keeping the warm indoor air in - its super important NOT to let this humid indoor air come into contact with anything cold (like the exterior siding of the house) otherwise it will condense and we'll be in serious danger of rot, mold, insects and all the other nasty things that water does to a house.

So: we Air-Seal!

|

| Parsons-Stevens Solar 2011 Decathlon: Taping the seams of OSB panels that line the walls and ceiling of the house |

There are lots of ways to air-seal a house. But the most important things are to make it continuous, simple to install, and durable. One way we've tried in the past is to use OSB sheathing on the interoir sides of the walls and floors as the air-barrier. Once the seams between OSB panels are taped, it forms a pretty good - very durable air-barrier. The problem is it isn't very easy to install and, depending on where you locate it in the wall - it can get in the way of things like electric, plumbing, insulation and all the other good things that are supposed to live inside the walls. Above you can see Siga tape being applied to interior OSB. I found this method difficult mostly because of how it affects the building process, not really for any detailing reason. You end up sealing up chunks of the wall too early in the build for air-sealing reasons, and there just isn't quite enough flexibility for my tast - though it is certainly super durable.

|

| The Pro-Clima Intello Plus Membrane. Its all in German so you know it must be good. |

So this time around we decided to try the

Pro-Clima Intello-Plus membrane for an air-barrier. One of the nice things about NYC these days is the huge community of folks interested in this type of building: we were very lucky to have the folks from

475 High Performance Building Supply right down the street from our office and the guys there were super helpful in detailing and spec'ing this system.

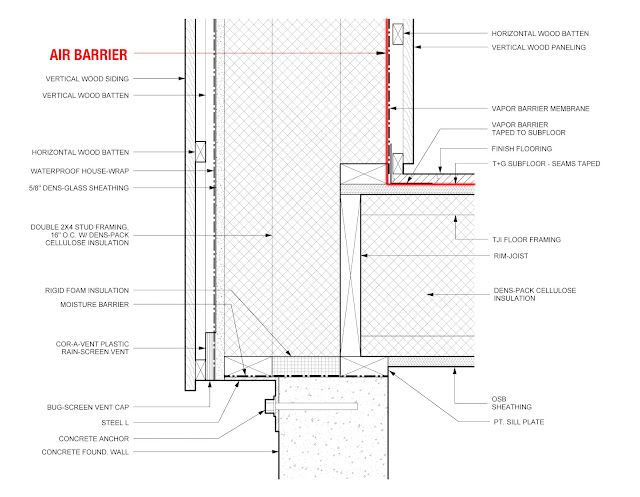

The Intello-membrane is a sheet that we'll be installing on the (warm) interior side of all our walls and the under-side of the cathedral ceiling. This membrane is not only our air-barrier, but also serves as our vapor-retarder, and the netting for when we blow in cellulose insulation. So three-in-one: not bad.

Below you can see a diagram of where the air-barrier is located in our wall assembly: inside the structural member, but under the finish layers. Note it connects to the subfloor OSB which we'll tape to form a full seal all around.

SO: run the membrane, tape all the seams, and tape the plywood subfloor seams: thats the strategy. We'll see how it works out on site.

While we aren't anywhere near ready for running the membrane just yet (we're still in the 'rough' part of rough-framing) - we did have to prepare a couple of areas to accept a good air-seal later on. Its important to think through all the air-sealing details long before construction starts so things can be prepared accordingly.

One area that requires a little prep is where we have interior partition walls intersecting our exterior (air-sealed) walls. Once these walls are joined we won't be able to run the membrane as easily - so everywhere this occurs we decided to run a strip of membrane behind the partition wall which will allow us to easily tape the membrane later.

|

| A strip of the Intello Membrane where the partition wall will intersect the exterior wall |

|

| Now that the membrane sticks out 6" on either side, it will make taping to it later on much easier. |

Similarly, today we started installing a ledger board for all of our second floor joists to hang off, and so we had to run a strip behind this ledger board all the way around the house.

|

| Carrie cutting membrane strips to go behind the ledger board. |

|

| installing the membrane with staples - on the left you can see the ledger board being installed over the membrane. |

All of this will hopefully make things easier and more effective when it comes time to actually install the full membrane. While we could have taped to the ledger and the partitions (instead of slipping behind), we thought running strips of membrane would actually be easier and a better detail in the end.

So far the Intello has performed great. Its already lived through a couple FIERCE wisconsin summer storms, and I have to say the Pro-Clima tape sticks like nothing I've ever seen before. So, so far so good. This is only the first step though, and things get really interesting around windows and doors - so look for that post soon.

|

| Jason, entry porch framing |